Cane Creek ViscoSet: Driving Stability

You’re about to read about bicycle stability, and Cane Creek’s contribution to the state of the art. Let me begin with a provocative statement:

Instability makes riding bikes fun, and fun-riding bikes.

Bike stability is a classic Goldilocks phenomenon. Just right is possible, and the more we understand how our bikes both take power, and transmit power (force over time), the more time we’ll spend enjoying, versus struggling, with them. I’ll elaborate what I mean by ‘power’; spoiler: it’s only a little about pedaling. Its a lot about predictability and confidence.

Below you’ll find this piece’s contents listed. Many of you will be reading my words for the first time, and I have to assume you don’t know anything about my credibility. I believe credibility is about experience, and I share my backstory to establish my history with bike performance and design, which is almost exclusively ‘practical’, versus ‘theoretical.’ If you wish to skip down to the technical discussion of Cane Creek’s ViscoSet, scroll down to Visco Vancing.

Backstory

Human Factors

Cane Creek, ‘Cycling’, and Mountain Biking: How did we get here?

Crash Trends

Visco Vancing - Technical Discussion

Ride Dynamics Insights

Conclusions

Backstory

For readers unfamiliar with my cycling background, a nutshell: I started out in the 1980s skidding and jumping my banana bike, breaking it, fixing it, and dreaming of a BMX. Instead, mountain bikes came into the frame, the ultimate ‘all-terrain’ machines. I bought a department store ‘MTB’, rode it on real trails, got hooked. I upgraded to another department store bike, broke and fixed it constantly, raced XC on it in 1992, confirmed I wanted to become a PRO. From that point on, a big chunk of my life was occupied figuring out how I could make my bikes hold up better, and get me to the finish line in one piece, faster.

‘90s MTBs were mostly terrible in terms of stability, but we didn’t know how to know whether they could be better. XC race bikes were fairly ‘static’ in terms of geometry, while downhill bikes were coming in hot in the mid-90s, and they were WILD! Suspension was in the mix, and with it, decisions to be made around geometry. Was it ok/good to put a 4” travel fork onto a bike designed for 2”? What would that do? Whatever, we’d find out! It was an exciting time, and innovation was the constant. I gravitated toward downhill racing, and put everything into that in ‘98, which led to a handful of years throwing myself down tracks in Ontario, Quebec, and the eastern US. There were so many variables at play then, we were riding production DH bikes that were not at all ready for prime time. All sorts of mechanical failures obscured specific system performance elements, like kinematics and geometry. After realizing I’d run out of talent and didn’t have what it took to transition from Elite to PRO (i.e., sponsored to salaried), I sold my DH bike and focused on trail riding, dirt jumping and ‘street’ for a while, which became all about building custom bikes, and distinct transition away from riding stock setups.

Bridging to stability, through the high-intensity innovation phase of the ‘90s and early 2000s, changes to components were making really obvious improvements to bike performance, pulling focus away from the nitty-gritty of geometry. Upgrading from a Rock Shox Quad 21R to a Marzocchi Z1, for example, would make a bike feel WAY more stable and capable, for example. The suspension performance improvement alone would eclipse nuances in geometry, including the significant geometric trail change that such an upgrade would render.

Once I turned focus to building really capable trail bikes (before ‘enduro’ was a discipline), I had done some DH races for fun on a 6” travel bike and even a hardtail. I had a clear sense of what I wanted out of my bikes’ downhill handling, but also needed to achieve climbing performance. I pulled this off well with a Manitou fork that provided 6” of ‘infinitely adjustable’ travel, activated from a lever on the bar. That allowed me to drop the front end lower for climbing, which changed the bike’s head-tube angle and trail. This ability to adjust geometry on the trail was really informative, and paved the way for what would come next: shoehorning big tires into road bikes for ‘spring classics’ races and dirt road riding, before ‘gravel’ hit the mainstream.

On road bikes, with so much more weight biased to the front wheel, and no suspension to confuse feedbacks, I was feeling geometry changes immediately, and learning the hard way when setups that ‘should’ increase stability (i.e., ‘bigger tires are more stable’) did the opposite. Before long, I was co-designing custom frames for spring classics and cyclocross, and tire options were slowly broadening to meet growing market demand. It was a chicken/egg thing: road bikes with caliper brakes couldn’t fit tires bigger than 35mm; that’s what my first custom bike could accept, using mid-reach brakes. Disc brakes opened things up, and with that, decisions. Then, 1X drivetrains became effective, introducing additional design options and decisions.

Human factors

FFWD to 2024. I’ve been making geometry decisions through various custom frame design processes for almost 15 years. I’ve done a lot of experimentation, and for a long time I’ve wondered about the feasibility and efficacy of using steering dampers to help manage stability challenges. Way back in the early 2000s, I had a couple friends using Hopey’s steering damper, and they swore it was a significant improvement for them. But they also ran really high tire pressures, which made me doubt their feedback. They said they struggled with their other bikes when they were adapted to the Hopey on their DH rigs.

Similarly, when I worked on Shaums March’s Schwinn DH race bike around 2001 (I was wrenching at Poison Spider Bikes in Ottawa), he was running Shimano’s Skunkworks prototype dual-rotor brakes. I rode his bike after replacing its smashed derailleur, and the brakes were WILD. Their bite was immediate, and it was easy to achieve full stopping power with a pinky finger. These were possibly the most powerful brakes ever produced and/or raced, and 23 years later, it seems clear that they defined the upper limit of braking power useful or desirable on a bike. Shaums told me he struggled to ride his other bikes, which ran the current gold-standard for performance, Hayes Mags. The sensitive actuation he attuned to on the proto brakes was specific and did not translate to other brakes. This meant he was constrained in his ability to ride these bikes back to back, which would be a performance issue during World Cup weekends, where there were Dual and DH events. The brake demonstrated that there is such a thing as ‘too much of a good thing’ in real world scenarios. The human factor - Shaums’ ecosystem of bikes - determined the relevance of the brakes’ power. If Shimano were to refine and release the brakes for commercial sale, would normal riders adapt fast enough to avoid crashing from overbraking? Would folks complain about them being too strong to make sense? It appears Shimano backed away, and ultimately landed on the Saint brake line, which was significantly less powerful than the prototypes.

The lesson here is bike technologies implicated in stability - which can also be categorized ‘safety critical components’ - are not merely ‘technical’. Stability doesn’t manifest distinct from a rider/bicycle interface and interaction. In practical terms, one bike isn’t inherently ‘more stable’ than another. Stability is an emergent phenomenon similar to time. Time is not ‘a thing’. Time is a concept we apply to experience, the perception of there always being a ‘before’ and a ‘to come.’ Really, time is a series of now-points; it is emergent. Similarly, stability emerges through interaction of bike, body, ground, and air.

On bicycles, where and how we position our bodies influences our bike’s handling phenomena, and there are almost infinite ways to manipulate body position. When we design bikes for riders as the sole ‘load’ they must carry, we can optimize geometry well if we understand the bike’s use-range well, and the rider holds to that use-range. If we design a bike to handle well with only rider load and also rider-plus-other load elements, our optimization challenge becomes messy. Similarly, when extra-rider loads , added to otherwise ‘standard’ bike configurations in the form of heavy batteries, placed here, there, and somewhere else, steering dynamics become, for lack of a better term, nuts. If we combine battery, loads of some shape, size, and mass attached all over the place, with new bike riders - because cycling is AWESOME, and more people are getting into it for utilitarian and recreational reasons - we have a ‘wild west’ situation manifesting around bike stability.

If you did the quick math, you’ll note that I’ve been involved in bike racing and technology ‘things’ for more than 30 years now. I’m clued in enough to know there’s a lot I still don’t know in this domain, and I will never ‘know it all.’ At the same time, I’ve learned a lot, and my lifelong mission is to share insight others can use to make bikes better, ride bikes more safely, and have fun. The fact is, there are many, MANY, poorly designed bikes on the market, being ridden by folks who don’t know a good handling bike from a bad one. I get it; we were all in that boat in the ‘90s on mountain bikes. There are no safety standards in existence that can guide manufacturers into ‘stable’ bikes, because this is an emergent phenomenon. You can do this with cars, planes, ships; all that exists. With bikes all you can do is set standards for individual components.

System-level stability can’t be quantified distinct from rider-bike interaction, and there is no ‘standard bike rider’. This means we are squarely in the ‘qualitative domain’, and experienced riders need to share information and insight about what does what under what conditions to help move the needle away from ‘known bad configurations’, and toward ‘better configurations.’ This is the role I occupy, and in case you’re wondering, yes, I spend all these hours writing ‘for free.’ I reach out to companies when they are doing things I think matter, and if they see value in what I do, they send me sample products to test, analyze, and write about. If we get along well and I believe in their mission and values, I seek partnership with them with the aspiration to be part of their continuous product development processes. Enter Cane Creek.

Cane Creek, ‘Cycling’, and Mountain Biking: How did we get here?

I go way back with Cane Creek, just like everyone who worked on bikes through the 1990s. Cane Creek (Dia-Compe at the time, re-named in 1995), brought the first modern threadless headset to market with the Aheadset in 1992, and went on to license the technology to other headset makers for the next 22 years. The company purchased the rights to the design from a bike racer and inventor named John Rader, and the Aheadset’s release coincided with the explosion of suspension fork development and scaling. Wow, did we ever sell a lot of Aheadsets along with Rock Shox, Manitou, and Marzocchi forks. Soon, Chris King were producing their first threadless headset, which steered clear of Dia-Compe’s patented wedge compression system. You won’t hear this often: King’s system was inferior. As geometries held quite constant in the road world, angles were moving all over the place on MTBs, especially as we fitted forks of varying lengths. Like I said, it was wild.

As a mechanic, I’d have customers come in with speed wobble issues on their road bikes, and it was a mysterious problem. Meanwhile, MTB riders never - yeah, I think this is probably accurate, never - came in complaining about bike handling and stability issues. On the road, there was such a thing as ‘just riding along’. On a trail, ‘just riding along’ was a ridiculous concept. The thing is, MTB riding on trails was more or less defined as an exercise in seeking stability across terrain that is inherently ‘unstable’.

Dirt, unlike pavement, literally crumbles apart when you push too much load into it. Mud yields to tires across a density range that influences displacement. Wet roots and rocks have organisms living on them that ‘behave’ differently across the range of weather conditions: dry and grippy on a cold day, greasy on a hot humid day. Part of the incredible allure and magical experience of mountain biking resides in our ability to reach a state of harmony with the trail and its constituents. Not dominance; harmony.

I hope I’m succeeding in articulating how tenuous the concept of ‘stability’ is on a trail. A given person can ride the identical bike setup on the same trail two different days and feel solid, committed, and in control one day, then opposite the next. It’s often difficult to discern whether that ‘opposite experience’ is about the bike, the trail, the rider, or some combination of the three. It takes a LOT of experience to parse these variables, thousands of hours. Most riders don’t ride that much.

In contrast, roads are rather consistent in their ‘stability’, not least because the majority of riders don’t go out when its raining, snowing, or icy. When you look at dry pavement ahead, you know what it’s going to do against your tires. When assessing reported instability phenomena, the consistency of road surfaces helps us isolate variables. For example, when a road rider descends a nicely paved road, reaches 65kph, and experiences speed wobble, we can ask whether the phenomenon occurred once, or multiple times. If multiple times, and in ‘normal operating conditions’ (no load added to the bike), we can defensibly state: ‘This bike is unstable above 64kph.’ If we want to be extra sure, our wobble rider can descend alongside a friend and determine whether that rider’s bike wobbles. Probably won’t, because let’s be real: people ride road bikes at and above 65kph all over the world every day, and speed wobble is not a common experience.

The road isn’t the issue, the bike is the issue. Try doing a side-by-side on a trail and devine bike stability issues between similar MTBs.

Bottom line, instability on MTBs tends to be interpreted as rider-influenced, and more about how the rider manipulates the bike across terrain than the bike itself. This is fundamentally because modern MTBs are manifestations of compromise. There is no bike in existence that can descend as fast as a DH race bike and also climb as fast as an XC race bike. This is not physically possible. Yet, descending and climbing comprise all forms of MTB riding other than DH. So every MTB is designed to bias performance on one or the other end of the spectrum, which is an exercise in compromise.

In contrast, road bikes don’t need to strike anything remotely resembling this compromise. A ‘pure road bike’ - which is a term we never needed until perhaps 10 years ago - can be built to handle and feel exactly as riders want (read, ‘good’ and ‘fast’) on climbs (both sitting and standing) and also handle really consistently and stably on descents. What works really well on pavement - up and down - doesn’t also work really well off-pavement, which is why we have other types of road bike now: cyclocross, all-road, gravel, touring. The ‘stability’ paved roads provide is the foundation for system optimization, and since good paved roads in 1960 were not different than good roads in 2020, road bike geometry has barely changed since the 1980s. In contrast, trails were never ‘constant’ or ‘stable’ in any sense, anywhere, and technology has advanced rapidly to improve all aspects of bike performance. MTBs have not been optimized, nor can they be in a manner analogous to pure road bikes. Again, this means riders will continue to struggle to know whether they are experiencing phenomena akin to 'speed wobble’, or if they are simply riding the bike wrong.

Crash Trends

Morgan Gale’s chopper’s geometry is very similar to the Schwinn low-rider a friend built 30 years ago, which I often rode to the deli on lunch runs. Imagine riding this thing. When you turn the wheel to the right, you angle it - the top of the tire moves to the right. The bottom of the tire is planted on the ground - it’s the ‘fixed point’ the top of the wheel is moving in relation to. Turning the bars/fork right SWINGS the headtube left in relation to the tire’s contact point. This creates lean, which enables the bike to turn. On bikes like this, there’s very little weight on the front wheel, very little grip. The headtube swings along an arc that resembles a smiley-face. Meaning, the swing is limited to the horizontal plane; it also moves vertically as it deviates from centre. It’s wild how much the headtube travels on bikes raked out like this. The reason they are rideable - though unwieldy - is that the front tire doesn’t remotely have enough weight on it to amplify steering forces.

When I started racing cyclocross I expected my MTB skills would help me go fast. I quickly found myself sliding out and crashing, often. I’d lose my front wheel in a turn, crash, and surmise that I needed to load/weight the tire more to achieve enhanced grip. It took a while to realize I was wrong. The issue wasn’t that my tires’ knobs weren’t gripping enough; they were gripping too much. The tire wasn’t sliding off the grass, it was tearing the grass out of the ground. The surface has a specific kind of stability, and its own yield-point. I was cornering based on what I read visually - dry and firm = push hard and grip - in the same way I did on trails. When the grass broke away under me, the ‘slip’ was sudden; more of a case of ‘shear’. When a tire shears, the bike’s steering geometry (read, ‘trail’) determines how the tire will react. In the case of the first ‘real’ CX bike I raced, the wheel would turn in more when the tire sheared, and very suddenly. This was a ‘power’ problem, because the wheel was transmitting force to my bars and headtube quickly. A rapid shift in wheel position (shear) initiated a swing of my headtube outward, which amplified the bike’s lean angle, front wheel turning in, and subsequent loss of grip. All the while, my feet were attached to the pedals, and my body mass was pushing the frame forward. The wheel would ultimately roll BACKWARDS as the crash fully developed.

I had to learn to turn less aggressively, to run lower tire pressures, to finesse grip. It was a different sort of dance. I also eventually learned that the fastest way to ride a cyclocross course was to use the least amount of tread possible, and achieve just the right amount of sliding in the lowest-grip turns. If you were sliding a bit you’d avoid overwhelming your tire’s casing (read, roll your tire) and tearing the ground out. I had a crash in Rochester once that was literally down to having too much grip on a very hard and grippy turn. My tire folded, burped, and I smashed my head into the ground. At the same tire pressure, a file tread tire would have gripped less than my intermediate tread, and my pressure would have held up. The magic of CX lies in achieving a perfect balance of in/stability across the course.

Alongside overwhelming tires on grippy surfaces, off-cambers, especially greasy grass ones, amplify bike geometry and rider position quirks. I’ve ridden across off-cambers and through ruts on all sorts of bike, from DH through pure-road. I know from experience that these surfaces are challenging and strain rider stability, but this is an emergent phenomena, not inherent property. Meaning, I can ride across an off-camber at speed on one bike with zero issue, while another bike would feel scary. If we want a bike to feel ‘fine’ in these circumstances, we have one primary move - design the geometry well - we can couple with a good / proper bike fit for the use-case. If we’ve struck our ideal balance of attributes / compromises possible, are there additional ways to manage the phenomena that lead to crashes?

There are two primary categories of crash:

Fore-aft weight distribution runaways

Side-to-side weight distribution runaways

For the latter, the issue is always centre of mass - rider - in relation to wheel contact patches, and our ability to keep the bike under us.

When the frame gets too far out from our centre of mass, we reach a point of no return - not recoverable.

Geometry decisions drive how much turning we can achieve per bar rotational angle and frame angle. This is about head-tube position, which is both lateral and vertical.

Turning happens when the headtube becomes non-vertical. When a stem is very short, turning the bar translates to minimal lean, and minimal headtube movement off-centre. In this case, we can have huge tires and shallow rakes, because we actually NEED a lot of steering amplification to make the bike feel nimble.

On a road bike, the equation is actually inverted. Small tires - doesn’t generate much if any steering amplification - require a long stem and heavy HT influence to steer. In addition, manipulating the frame in a turn - feet on pedals - achieves steering - from frame through fork to contact patch. In this scenario, when a tire loses grip suddenly, the HT swings too far and creates too much lean too fast. It is a power problem - force over time.

Visco Vancing

That same ‘real cyclocross’ bike I reference above was a flexible steel Pinarello. It had a steep 74-degree headtube angle and very short 35mm fork rake, which amounts to 63mm trail. On paper, that’s pretty good, but that bike rode very differently than others I’ve spent time on with the same trail figure. The rear end was slightly misaligned, and my rear tubular had a wobble in it (I wasn’t yet decent at mounting tubulars). When I’d ride the bike with no hands the rear wheel’s wobble would influence the front wheel via the head tube’s control over the fork’s steerer tube. A speed wobble would develop rapidly. This informed me that weight bias and frame inputs are implicated in speed wobble.

I didn’t have this issue with subsequent bikes, but I keenly noted Jan Heine reference to flexible steel randonnee bikes exhibiting speed wobble. In Bicycle Quarterly he began mentioning swapping from super smooth Chris King headsets to needle bearing headsets. Interesting. There had to be some sort of energy damping happening there. And, perhaps those bikes were optimized for front loads, and without those loads that bike lost stability? Maybe test riders were mounting shorter stems and exacerbating the issue?

Speaking of Jan Heine, he also gets credit for introducing high volume, high quality tires to road cycling. First, it was 28mm, then a 30mm tire, which was really ‘out there’ around 2008. These tires fit onto some road bikes, and had subtle effects on their handling. I co-designed a custom Steelwool for 30s, and learned a heck of a lot through that process and years on the bike. Rim brakes constrained how much volume we could fit into these bikes, so things didn’t really start to get wild and whacky until disc brakes came in and scaled.. Normally, if we’d shoehorned a big tire into a cyclocross bike, like 35mm Stan’s Ravens I trimmed to work better in my first Steelwool Truffle Pig, they were off-road tires. Certainly, they were not ultra supple ‘slicks’ like what would become today’s Rene Herse Bon Jon. As I’ve covered elsewhere, stiff and knobby tires don’t create weird handling phenomena like their superlight slick cousins. There were no 35mm ultra-supple tires on the market while we were all stuck on rim brakes, so we couldn’t yet know what they’d do to handling. Disc brake opened up room for 35s and beyond, and before I knew it, I was testing 700c x 44mm Rene Herse Snoqualmies on my gravel bikes. They were a far cry from 30mm Grand Bois, or 35mm Ravens; they needed different geometry. One bike could now fit anything from a 32mm tire to a 48mm slick; it was a recipe for wild instability issues to arise.

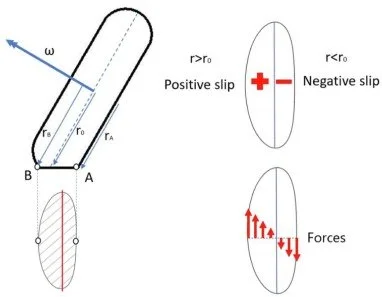

Enter twisting torque.

With so many variables at play, it’s not surprising that it’s actually quite challenging to make two identical bikes feel identical. To a highly sensitive rider, very subtle differences between bikes will be perceptible, and one’s ability to calibrate comes down to experience, skill, and cognitive endowments. If I’m to characterize what a ‘good bike’ feels like to discerning riders, across all performance - i.e., not city bikes, utility bikes - categories, I’d say the following:

Good bikes feel fast and react predictably across the relevant range of rider input and surface feedback.

As discussed above, numerous developments in cycling technology over the last decades half-century have mainstreamed new variables that complexify ‘the bike stability problem.’ The issue I am most concerned about is steering stability, primarily pertaining to drop-bar bikes. However, I continue to find MTBs and fatbikes very informative; they help me understand the physics at play.

For example, the fatbikes my friends and I ride on mostly snowshoe trails over winter use 4.5 - 5” wide tires. We run them down around 3PSI when conditions are ‘soft’, which is most of the time. At this pressure, our bikes need front-end geometries that encourage steering amplification. This is because leaning doesn’t actually translate to compressing the front tire on a stable, firm surface. The snow compresses, and the friction of snow against rubber is low. At the same time, when our trails are pocked with depressions and holes from people walking without snowshoes (‘post-holed’), our front tires get pulled around as we pass over them unevenly. To my mind, my fatbike’s front end geometry is what it should be for the tire setup I ride, but it could use some help managing high-velocity deflecting forces. The issue I’m keying in on here is ‘predictability’; fatbiking feels scary when snow conditions create unpredictable front wheel deflections and ‘pulls’ we have very little margin to correct. After all, we’re often on trails about two feet wide, lined with trees. Thinking back to the Hopey steering damper, which was designed to absorb energy from these sudden deflections, I wanted to test Cane Creek’s ViscoSet.

On dropbar bikes, the challenge of defining geometry boundaries against tire dimensions is far more complicated. I believe this is fundamentally because dropbars place hands and weight bias further forward in relation to the front axle and tire’s contact patch than MTBs of any variety. This bias amplifies steering phenomena, which is great and ideal when rolling on small tires that have low inherent twisting torque. The following list covers the phenomena and dynamics I’ve honed in on:

As tires increase in volume, twisting torque increases.

Knobs absorb / damp twisting torque.

Firm, stable, grippy surfaces increase twisting torque.

Soft, unstable, slippery surfaces decrease twisting torque.

Twisting torque is implicated in self-correcting steering, when it helps position the frame under the rider’s centre of mass

Twisting torque forces exceed self-correcting benefits when the tire’s contact patch transmits force to the headtube and handlebars too fast

Cane Creek’s ViscoSet is designed to slow the fork’s rotational speed, and thus address the ‘too fast’ issue. In the case of a bike like my Devinci fatbike, a ViscoSet wouldn’t be a ‘corrective’ intervention, but an ‘optimization’ one, if it could do one specific job: reduce the force and speed of wheel deflection / handlebar rotation. I would want steering to feel completely normal when seated and standing, and ‘want’ to keep steering straight when unevenly loaded, as in the case of post-holes and ruts. I put some questions to Cane Creek to ensure I had a good sense of what they were aiming for with the ViscoSet:

Q: Is the ViscoSet’s damping meant to provide 'light/normal steering resistance' under typical input, or 'heavier'?

A: It's definitely a heavier level of resistance than a normal headset. At low speeds, steering input feels more or less normal, and quite smooth. At higher velocity inputs though, you can really feel the friction plates doing their job. They seem to add more resistance the harder and faster you try to shift them. Think of it like a non-Newtonian fluid, or like the fancy material that knee pads are made of these days that actively hardens on impact, but remains soft and pliable otherwise. We also have various "tunes" of shim stacks available if you want to change the level of damping.

Q: Is damping wheel deflection energy an objective for the Visco?

A: Yes - if I understand your meaning correctly. It's meant to help combat high-frequency wheel & steerer oscillations, aka, speed wobble. Also, to help keep these bikes tracking straight on rough/uneven surfaces. If a lightweight rider nails a pothole with a front basket loaded with groceries - the force from the hole is less likely to rip the handlebars from the rider's hands.

Q: How can a rider determine whether HS preload is correct with the Visco?

A: There is a specific torque spec for Visco. Tighten the preload bolt to 2.5nm-3.5nm.

Q: Should riding no-hands feel normal with a Visco?

A: Yes. As mentioned, subtle, low speed inputs are allowed to exist fairly normally. The subtle corrections needed to ride a bike in a straight line are not very heavily influenced by visco - whether or not your hands are on the bars. In some cases, riding no hands is actually easier with Visco! That said - it's always safest to ride WITH your hands and we didn't factor this cool move in to the design or testing process. So user discretion is advised.

Q: Is there a typical 'break-in' period for the Visco?

A: No - not in any measurable way.

Q: How can a rider tell whether the Visco is 'working' as a damper, versus mimicking an overtightened headset?

A: The smoothness of movement is the dead giveaway. Worn out, damaged, or overtightened headsets don't move smoothly and quietly. They bind and often are paired with an obvious level of rough feeling in the bearings, sometimes even an "indexed" feeling. Visco should feel quiet, smooth, and even in the way it moves.

For my first-generation T-Lab X3, I wanted to test whether the Visco damper could increase stability when rolling through ruts. Ruts are tricky because they exert force on tires akin to leaning the bike on a flat surface. If a damper could make the bike easier to keep straight on snirt roads, which at time involve frozen ruts and/or ice, I would get a good sense of the solution’s applicability for use-cases like cyclocross and MTB.

Cane Creek sent the ZS56 ViscoSet for my Devinci Minus fatbike, which is a lower assembly (above left). That bike has an integrated bearing up top, which doesn’t afford the space for the ViscoSet design. The 1.5” bottom of the headtube offers enough internal space; you can see above that the bearing would reside inside the headtube. The bike’s fork has a carbon steerer tube with integrated crown-race, which was a potential match for the Visco; it was a bit of a gamble. I had to mount the headset and re-install the fork to tell whether the fit would work, and it was just off enough to be a no-go. That ruled out testing the solution on the fatbike, leaving my T-Lab.

The ZS44 Cane Creek provided for my X3 is for the top of the headtube, which is 1-1/8”, bearings external to the frame. Cane Creek’s website enables you to walk through figuring which cup is compatible with your frame. Not all frames can accept a ViscoSet.

As you can see above, I paired the ViscoSet (with mid-tune) on my X3 with Cane Creek’s 110 lower headset cup. This was my first interaction with a 110, summed up in one simple word: wow. I have lots of experience with Chris King headsets, which many consider the gold standard; the 110 exceeds King in refinement, to my eye. I’d been on an AER internal headset on another bike for a couple years, and noted its lower crown-race seal did an impeccable job keeping contamination out. The 110 uses the same seal - as does the Visco - and everything about the headset feels perfect. Hence ‘110’; the headset is guaranteed for life.

You’ll also have seen the Ancora steerer tube expander plug above, which sets also sets the high-bar. Believe it or not, many bikes running carbon steerer tubes are set up with expander plugs that are actually shorter than fork manufacturers indicate as necessary. These plugs are meant to provide structural support to the steerer, which means they need to pass all the way through the stem clamp; 45mm or greater plug length is indicated in TRP’s fork warranty information, for example, and the Ancora’s insertion length is 46mm. Its build quality is impeccable, and its significantly lighter than the other long plugs I’ve procured over the years.

Ride Dynamic Insights

Riding the ViscoSet on my T-Lab X3 through 2023 didn’t go the way I expected at all. In short, I didn’t want to ride the bike; it was wild. And it was a really informative experience.

My first impression was obvious: damped steering. My bike normally feels pretty nimble, sort of like a typical skateboard’s dynamics. With the ViscoSet the bike became a longboard. Or if a snow analogy works better, the headset had the effect of making my bike feel like a long ski or snowboard. In other words, it was as if my wheelbase had grown. This comes down to the headset’s ability to keep the front wheel tracking straight and in line with the back wheel when the bike is leaned. When the wheel contacts impediments like pebbles while leaned over, the headset damps the force that would normally cause the head-tube to swing outwards, increasing lean and the wheel’s ‘inclination’ to turn in, out of alignment with the back wheel.

Instability makes riding bikes fun, and fun-riding bikes.

What I was hoping for with the ViscoSet was resistance to high-energy inputs, like deflections that would require very fast reaction to get the front wheel pointing straight again. My bike’s geometry is the opposite of ‘squirrely, so I didn’t want to calm the steering down all the time, as a ‘linear’ damper would. A ‘progressive’ damper functions like a shock with speed-sensitive damping. Good shocks have slow and high-speed compression damping, and a lot of slow-speed compression damping mutes pedaling and body-weight inputs, while high-speed damping controls impacts taken by the wheel. A high inertia impact must be damped with a lot of resistance to control the rate of compression through the wheel’s travel range. A low inertia impact needs to be resisted less forcefully, to enable to wheel to roll, versus bounce over the obstacle. Bikes that rely on a lot of slow-speed compression damping to control pedaling inputs can feel ‘dead’ under the rider. This is because pedaling input gets absorbed by the shock’s damper instead of transmitted to the rear tire’s contact patch.

It turns out damping the frame’s steering heavily influences how it feels to PEDAL the bike too!

This is not what I expected at all. Once I’d adapted to the slower/muted handling feeling the ViscoSet provided, it was clear that it was providing increased stability, particularly when the front wheel was dealing with uneven loads, like ruts and rocks impacting the tire’s shoulders. I deliberately tested the setup on packed snow and ice, and there’s no question it helped maintain stability.

The flip side of the bike’s enhanced stability was how it felt under pedaling load. In short, the bike felt slow. Two factors drive this (keeping all components constant):

1) Steering stability - the more stable a bike feels, the less we perceive speed

2) Pedaling efficiency - more energy absorbed by frame/fork translates to less energy driving the bike forward

The way #2 plays out comes down to the fact that whenever we’re riding bikes in a straight line, we’re not really riding in a straight line; the front wheel is always deviating side to side slightly as we pedal. This deviation depends on how straight (vertical axis) our knees track, how much/whether we rotate our hips, and whether our elbow angle is held constant. In other words, it depends on how the ‘motor’ is moving on the bike.

In my experience, really stiff bikes require angling the frame off vertical axis when we try to deliver high power, especially if cadence is not high. This is because pedaling drives force into the centre of the bike, not just ‘straight down’. When the pedal is at 6-oclock, it’s at the end of a long lever arm that pushes the bottom bracket along the horizontal plane. If a frame were to be so stiff as to completely resist this side-load under a given rider’s input, the bike would feel terrible: it would be impossible to get into a rhythm on, and it would hurt the legs. I have tested bikes that fall somewhere on the extreme ends of this spectrum. The worst road bike I’ve ever ridden was way too stiff. Climbing it was horrible, it was only tolerable under full sprint loads, and it consistently hurt my legs in circumstances no other bike had or has since. On the flip side, the most flexible bike I’ve ever ridden felt great climbing, and never hurt my legs in the same way. Yes, my power would degrade as I pushed through rides and races, but my legs didn’t hurt.

If you look at the video above, you’ll see Jens Voight consistently ‘micro-steer’ as he delivers power. This is Jens in breakaway situations, trying to put out the max power he can sustain, which is very much about rhythm. To my eye, Jens’ bike is quite stiff, and at his moderate cadence, he needs to steer in order to angle the frame and increase the leverage his pedal force exerts into the bottom bracket. The downtube and seat-tube deflect, storing kinetic energy (think leaf-spring), and return some proportion of that kinetic energy as the other pedal comes around. Jan Heine coined the term, ‘planing’ for this dynamic.

I raise planing to make explicit that steering and pedaling are intricately bound together. I wanted to test the ViscoSet on a (relatively flexible) bike I know very well and ride across a broad range of surfaces, with the hope that it would offer progressive damping. Instead, it provided linear damping, which meant it always affected my bike’s feel. This translated into pedaling input being damped constantly, which felt annoyingly slow.

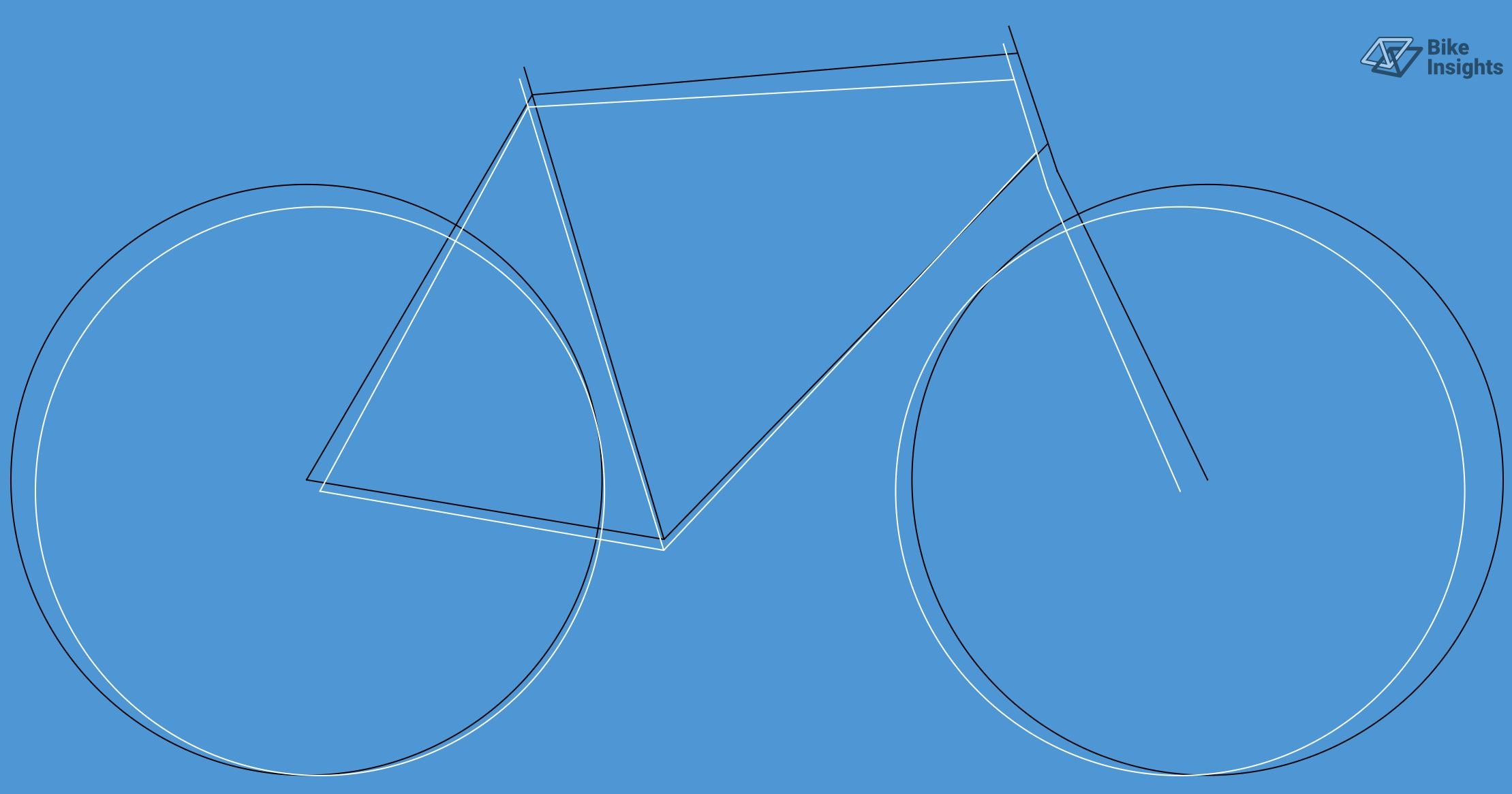

The bike’s increased stability was cool, but I didn’t want to ride it, so it was irrelevant. However, while the ViscoSet didn’t transform my bike’s dynamics the way I has hoping, I don’t think of this experience as having been a waste of time or failure, remotely. One of the most fortuitous results from the experience is a deeper understanding of how head-tube angles (HTAs) are implicated in pedaling efficiency and bike feel. The contrast of damped and undamped steering has helped me understand why road bikes really ought to hold to HTAs on the more vertical end of the spectrum, versus the slacker angles that well for gravel and all-road bikes.

The closer to 90-degrees the HTA is, the less steering is implicated in leaning the bike (this is also proportional to tire volume - a 28mm tire doesn’t amplify steering as it’s leaned over nearly as much as a 35mm tire does). Less steering means less energy lost as waste heat (friction). While climbing out of the saddle on a road bike, body weight shifts over the front axle, and the front tire is loaded much more heavily than usual. It needs to be able to angle under us (see planing), which involves turning the bars slightly. A 73-degree HTA and fork with typical road rake (43mm) puts the tire’s contact patch at the end of a ‘shorter lever arm’ than a longer gravel fork with 52mm rake, in a 71.5-degree HTA (as illustrated in the overlay below - Cervelo S5 / T-Lab X3). Running the same front wheel between these two example front-ends, the road format will be more efficient. Less energy will be lost through fork flex and headset resistance. With thousands of hours under my belt on my custom geometry T-Lab X3s, I’ve asked myself many time why I wouldn’t want to adapt ‘modern’ geometry to a custom road bike. The ViscoSet helped me understand why I’d want to hold to fairly conventional road geometry, with small adjustments for larger tires (28-32mm being the new norm and sweetspot).

Conclusions

Unequivocally, for riders who’s bikes are twitchy/nervous feeling, especially e-bikes and those carrying loads, the ViscoSet will help make the bike feel more calm and controlled. These use-cases are what it’s designed for, and the product absolutely hits the mark. If you’re riding a bikepacking setup, like a large saddlebag - which is very common - the ViscoSet would definitely help control unwanted steering transmitted from the saddlebag’s sway to the head-tube. With pedal assist, I imagine the ViscoSet’s influence on pedaling efficiency would be eclipsed by the bike’s enhanced stability; in other words, riders wouldn’t notice any impact on pedaling: win/win. If I were a product manager for a bike company selling quality e-bikes, I’d be compelled to sell them with ViscoSets.

Looking back, I’m wishing I’d remembered that the ViscoSet’s resistance is tunable. They provide clear technical drawings on the assembly, and it looks like removing a c-clip is the most challenging part of the process required to swap around shim orientation, moving toward the lightest or heaviest tune. While the mid-tune is too heavy for my more flexible T-Lab X3, the light tune might have felt fine. I suspect that the bike’s gravel-optimized front end geometry amplifies the influence of steering damping on pedaling efficiency.

My primary takeaway from this most recent Cane Creek experience is that the company is all about quality, and I have nothing but respect for what they do and how they do it (making everything in the US). My ViscoSet test took an unexpected path into a steering dynamics rabbit hole, for which I am grateful. Bikes are wild contraptions, and a lot of Cane Creek’s work centres around managing instability in predictable ways. Suspension, brakes, headsets; they are all about bringing predictability and consistency to inherent instability, and striking that balance we experience as ‘fun’.

Thanks to Cane Creek for enabling me to undertake this process; keep doing what you’re doing!